The Grizzly G0704 is one of the most popular mills in the hobby market. It offers a good combination of features: a motor that might actually run 1HP, a decent work area; 6-7/8" of Y travel and 18-7/8" of X. The Z-axis lifts 11". Plus, it comes at an attractive price, $1250 today: 4/23/17. It has become a popular machine for conversion to CNC for home hobbyists, with most people using at least some of the plans at http://migration.g0704.com/, created by "Hoss", Daniel Kemp.

There are also other ways to do this: Automation Technologies sells two different kits of the parts (with the Y axis motor mounted on the front or the back) so that you don't have to build as much as I did. I used their stepper motors and controllers, but gathered all the parts and built my own controller box. I bought the ballscrews from LinearMotionBearings2008 (Chai is the guy to talk with) and built my own motor mounts, ballnut mounts and all the other metal parts I needed.

A project as large as this deserves an opening "introduction" and conclusion - to the degree that a project as large as this is ever finished. The introduction is the first post in this series

June 7, 2015

Introduction; explanations of what I'm doing and the start of the project

September 26, 2015

A trick on the lathe for threading

October 17, 2015

Cutting pieces

November 18, 2015

The CAD/CAM process

February 26, 2016

GCode for cutting a motor mount with video

March 9, 2016

Leading with my mistakes - I screwed up a piece

March 12, 2016

Followup wherein I clean up my mistakes

April 6, 2016

I change directions and start over. This is the start of phase 3, the way the conversion proceeds.

April 17, 2016

Rough cutting all the new phase 3 parts

April 20, 2016

Making parts for the new phase 3 approach - a puzzle on the X-axis ballnut mount

April 22, 2016

The answer to puzzle on the X-axis ballnut mount

May 1, 2016

Just the last paragraph - cutting the Z-axis ballnut mount. The rest is financial.

May 8, 2016

Boring the Y axis ballnut mount

May 13, 2016

Boring the Z-axis ballnut mount.

June 4, 2016

Issues with the Z-axis ballnut mount and fixing them.

June 8, 2016

More work on the phase 3 pieces

June 15, 2016

A wrap up of cutting the metal

July 7, 2016

Redesign of the X-axis cap

July 13, 2016

The new X-axis end cap is prototyped and will work

July 18, 2016

All of the parts for the phase 3 conversion are completed!

July 24, 2016

Setting up to powder coat the metal parts

July 27, 2016

First parts painted

July 30, 2016

Finishing painting the parts

August 5, 2016

Top level assembly work - prepping the Y-axis ballscrew

August 8, 2016

Work on the chip tray.

August 14, 2016

Completion of the chip tray

August 22, 2016

Modeling the shop layout

September 4, 2015

Update of the shop featuring a rolling base on the G0704

September 10, 2016

A milestone - getting the computer to run the motors on the benchtop

September 18, 2016

Modeling the controller box

September 27, 2016

Modeling the controller box back and bottom panel

October 3, 2016

The controller box mostly built

October 4, 2016

With Hurricane Matthew bearing down on us, I continue to cut out the DB9 connectors on the controller box back panel

October 17, 2016

More controller box

October 25, 2016

Controller box works on its first test - complete with moving motors

November 1, 2016

The controller box is done. And it's (part) orange.

November 16, 2016

Tear down and rebuild of the G0704 begins

November 20, 2016

Setting up to mill the oil channels

November 29, 2016

Talking about the scariest hole in the whole project -1/8 diameter and 4" long; trouble with the Sherline mill helping build this

December 10, 2016

Got the Sherline mill fixed, so back to cutting metal

December 20, 2016

Drilling the scariest hole in the job and overview of the way the oiling system is designed

December 22, 2016

The ballnut removal tool saga - for installing the Y-axis ballscrew

December 29, 2016

Plumbing fittings in the cross slide

January 3, 2017

Attaching oil fittings

January 13, 2017

Tear down stories - repacking the spilled balls out of a ballscrew, or "reballing the nut"

January 17, 2017

The mill torn down to a base, a Z column on it, headstock on a bench, then rebuilding begins

January 17, 2017

The Z-axis moves under CNC control - while the mill is apart

January 25, 2017

Starting reassembly and oil system clearance issues

January 29, 2017

Oiling system clearance problem fixed and more debugging

February 1, 2017

The XY table is moving

February 2, 2017

Construction is complete! The mill moves and works

February 8, 2017

Tweaking and improving the mill begins

February 13, 2017

Tweaking and improving pt 2

February 18, 2017

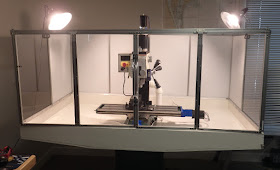

Modeling and designing the enclosure

February 25, 2017

Working on the enclosure

March 1, 2017

Cutting some enclosure pieces on the mill under CNC control

March 8, 2017

Building the enclosure

March 14, 2017

Enclosure at 90%

March 20, 2017

Finishing the enclosure and some other notes

March 29, 2017

Oiling system running properly, and the choice between misting and flooding coolant

April 15, 2017

Setting up to install the Fogbuster

April 19, 2017

Running the Fogbuster for the first time

April 24, 2017

Concluding notes on the project.

May 16, 2017

Adding a Rotary Axis to the CNC G0704

September 9, 2017

Demonstrating a pendant to control the mill, implemented with a Logitech Rumblepad 2 game controller.

No comments:

Post a Comment