I really told myself not to post this until I was sure the crankshaft was done, but since I want to be an Alec Baldwin-free zone and I'm not aware of any space news today, writing about the crankshaft is about all I've got.

The biggest milestone is that I'm through with turning between centers, the lathe dog and all that. The final sizes for the sides of the counterweight holders are done. The remaining operations are to cut the keyway on the long shaft side, cut both sides to finished length, and drill and tap holes for the mounting screws that hold the crankshaft counterweights in place.

I probably was too zealous in editing out dimensions in this graphic from a few weeks ago. But the long side (left) is 2.73" and the short side is 2.27". The keyway (side view on the left) is 3/32 wide and 1.25 long. The screw holes are visible at the top middle of each side as hidden line. The print calls out #5-40 screws, but since I don't have any of those while I have a parts cabinet drawer full of #4-40, chances are that's what they'll get.

I started here:

(Ackchyually ... I started from a 1-1/4 in diameter round bar and threw away more weight in chips than I kept. This was after cutting it into a slightly oversized rectangular bar).

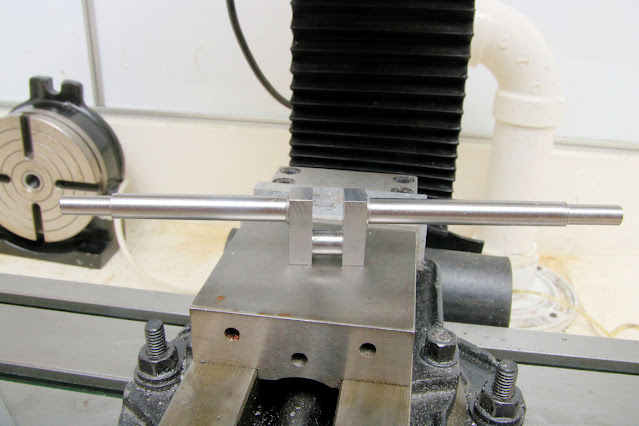

Today, it looks like this.

The smaller diameter ends on both sides going to get cut away - they're way beyond the amount that ends up in the part. They were put on to help position the lathe cutters better than when the bar is constant diameter along the whole length.

As always, I expect to be able to finish it real soon.

3994

Good to see you're still chugging away at this (pun intended).

ReplyDeleteI'm guessing the finger is healed?

This is what should be taught in high school shop

ReplyDeleteLooking good!

ReplyDeleteWhile it is totally your deal, I would have severe misgivings about holding on counterweights with screws at all, let alone under spec ones. Maybe screws could be added to the sides which would be stressed in shear. An explosion shield could be a conversation starter. Neat work and problem solving.

ReplyDelete