It has been virtually a month to the day since my last update. It's not like I completely stopped working on it since then, but I had to stop working for longer than a day or two several times. I've written several times about the biggest project so far this winter, the new antenna, but there are others. Basically, as we come across some aspect of house maintenance that requires a lot of work outside, or with the doors open, we try to put it off for "when it cools off." That's not always possible and the one I just started on, some rotten wood on a door frame, looks like I should have started in on that when we found it last May. It looks like it might well go several days as well.

The cylinder isn't done, but I've overcome the big thing that was keeping me from moving forward, which was getting more repeatable measurements. The thing that helped me to get more repeatable (more precise) measurements is this YouTube video from a guy called who calls his channel Abom79. He demonstrates a technique that I was able to pick up with some practice, and dropped my measured value spreads to .0002 to .0003 inch. Machinists refer to that as "2 to 3 tenths" but that's "tenths of a thousandth." That decimal place means that a "tenth" is one hundred millionths of an inch.

The diameter at the top of the cylinder (farthest from the lathe chuck) was 0.9962 while the diameter at the chuck end of the cylinder is larger: 0.9976 or .0014" larger - so there is a taper. The target diameter is to be 1.000" throughout, so I could have worked to enlarge the bore closer to that, but I elected to finish turning the features on the cylinder and cut it off. This doesn't mean I can't do anything to enlarge the cylinder, just that it will require meticulous setup.

The most important point is that a 1.000" bore is a target. I'm not Gigantic Motor Car Corporation running two production lines, one making cylinders and the other making pistons, so that every piston must fit every cylinder ever made. I fit the piston to the cylinder.

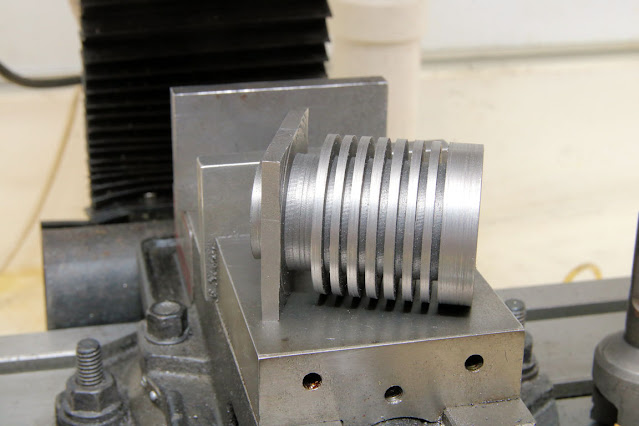

The cylinder off the lathe looks like this:

I did one operation since that picture, drilling the mounting holes in the square flange at the bottom (left). They're not quite in a square pattern, the same distances from each corner in X and Y; they're in a rectangular pattern. There are four more holes to drill and tap. These are for four #5-40 screws and go on the right end in this view; those screws are how the cylinder head attaches.

I've seen that Abom79 telescoping gage video and I suspected he has a great technique. May I suggest you switch to lapping to make the cylinder a truer cylinder and to size: https://www.gadgetbuilder.com/Lapping.html

ReplyDeleteYeah, that's what I was thinking. I'm between making one like that page says and the three-stone brake cylinder hone that I have.

DeleteWith a brake cylinder hone I would be nervous about making the hole bell-mouthed, because most of the time some of the hone will be outside the mouth and eating away at the edge. If it were mine I would make a hone which puts the thick end at the bottom of the hole, where you can move it around the whole cylinder.

DeleteGood video.

ReplyDeleteThanks!

Abom79's channel is a wealth of info and technique. He does some big stuff, which is nice contrast with a lot of the guys doing 'home machining' or 'hobbyist' machining. Recommended.

ReplyDeleten

I've been watching Abom's channel for a little over a year. One of the best channels I've stumbled onto randomly. I find it soothing.

ReplyDeleteI’m glad you found my Abom79 video recommendation helpful.

ReplyDelete