While not something tied to an explicit announcement, Ars Technica's Eric Berger reports that the first SLS mission has slipped into 2022. A source told Ars the best-case scenario for launching the Artemis 1 mission is spring of '22, with summer being the more realistic target for a test flight of the heavy lift rocket and Orion spacecraft. If I may quote myself, “If NASA and Boeing are lucky and there are no more failures that eat months at a time, Artemis-1 might fly by the fall of 2022.” My reasoning was simple. The schedule to launch before the end of this year was never changed after their time at Stennis delayed completion of their Green Run test by nine months. I just added nine months to the announced "before the end of '21" date.

Publicly, NASA is still saying before the end of '21. They're also acknowledging the schedule is slipping and the Covid problems are a factor.

NASA's Kathryn Hambleton acknowledged that the space agency has seen schedule slips. "The agency continues to monitor the rise of COVID cases in the Kennedy area, which, combined with other factors such as weather and first time operations, is impacting our schedule of operations," she said. "Moving step by step, we are progressing toward launch while keeping our team as safe as possible."

There are still many hoops to jump through between where they are now and being able to launch. For example, earlier this summer, when the vehicle was stacked on the cape, instead of adding the Orion spacecraft, a mass simulator was added. The mass simulator is for vibration testing of the assembled rocket to ensure they understand the difference between the natural vibrations of the full stack versus those caused by external forces. Berger adds:

NASA originally hoped to complete this work in July, but Hambleton confirmed to Ars that this vibration, or "modal" testing, is ongoing in the Vehicle Assembly Building at Kennedy Space Center.

"Complete in July" has turned into September - if they can even meet that. Eric Berger goes into details on several of the tests that need to be completed before launch, so by all means read over there if you're interested. He also goes into a refresher on the history of the program.

My view is that the program was created as a giveaway to companies that lost their income streams when the Shuttle program was canceled, and since its start I'm not aware of a single milestone they've met and a single budget they haven't overspent. What NASA needs to get SLS launched before next September is for schedule items to be moving left on the schedules - earlier in time. Not only have things like this vibration testing slipped right, I don't think in the entire history of the SLS program that anything has moved left on the schedules.

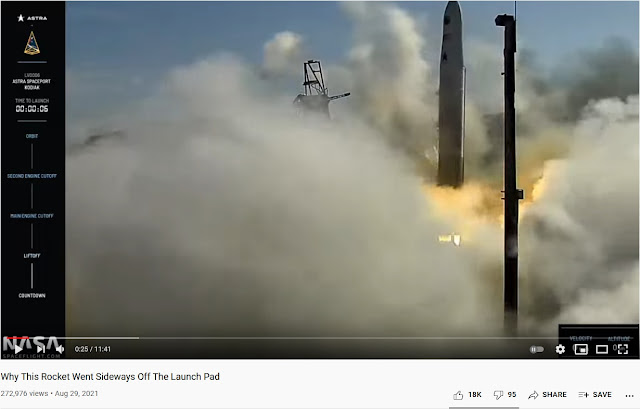

The launch vehicle stage adapter for NASA’s Space Launch System rocket is integrated with the core stage in June. NASA Photo from Ars Technica

One of the early proponents of SLS was (of course) Florida Senator Bill Nelson - who is now NASA administrator. The legislation starting the program was passed in 2010 and SLS was supposed to have flown by 2016. Nelson said,

"This rocket is coming in at the cost of what not only what we estimated in the NASA Authorization act, but less,” Nelson said at the time. “The cost of the rocket over a five- to six-year period in the NASA authorization bill was to be no more than $11.5 billion.” Later, he went further, saying, "If we can't do a rocket for $11.5 billion, we ought to close up shop."

Over a decade later, that $11.5 billion has ballooned to over $20 billion and 2016 has transformed to very likely '22. They can't do a rocket for $11.5 billion and the shop is still open.