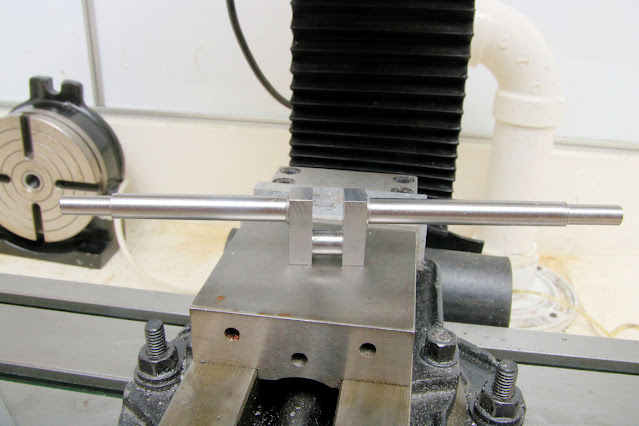

This is not an update to the 1 by 1 engine I've been tracking, at least not

exactly. I didn't do much to the cam shaft at all this week. Last

Saturday, I concluded my update by saying it should be done "tomorrow" - meaning last

Sunday. Nope.

I did some more reading and decided the cylinder I'd been turning (more

precisely called a

journal bearing) needed to be not only reduced to the right diameter but almost left with a

polish. That means sandpaper. I did some research and found that

the most common way of getting sand paper into a place like that and minimize

the chance of repeating my finger injury (or worse) is by gluing sandpaper to

a Popsicle stick. Well, there's two of us in this house and neither of us eats

Popsicles so it became a question of how I got one.

While sitting in the shop, I almost put my arm on my 3D printer when my brain

said, "it's a plastic Popsicle stick maker." And so began a week of

misadventures. A comedy of errors that, like most of them, wasn't funny

at all.

If I'm going to print anything, I need G-code file and to get that, I need a 3D solid

model of a Popsicle stick. This didn't take long, and I quickly made a

version 1 of what I started calling the Fat Popsicle Stick - because I wanted

to put a nice handle on it.

The dimensions aren't there, but it's 5 inches long, the thick part of the

handle is 1/2" tall, and the stick portion is 0.4" wide by 1/16" thick. That

number was completely pulled from thin air. I mean, I have had Popsicles,

just not in the last 35 years or so. They seemed about that thick.

So Tuesday it was time to print it. The print failed. I watched it

for the first few minutes and came in to do other stuff during the remaining

hour the print would take. Just as I was about to go check on it Mrs.

Graybeard came in to tell me the thin, stick part was off the table. I

went out to check it out and figure out what to do. I thought about

putting a spot of glue under that end and pushed on it to see how flexible it

was. When I did that, I popped the whole stick off the print bed.

No choice left but to kill the job.

Except that it was about 3/4 done and probably usable. So I gave it a

try and found two problems. First, it was too wide. The design was

0.40, but it came out a little wider. When I wrapped sandpaper on it, it

was too close to the .438 of the journal. The second problem was that it

felt too flimsy.

Within a few minutes, I had a redesigned "Ver. 2" stick ready to print.

I doubled the thickness of the stick portion to 1/8" thick. Stiffness in

bending here is proportional to the fourth power of the thickness, so doubling

the thickness should make it 16 times stiffer. The minor change was to

drop the width to 3/8".

Except that I noticed before I left the first time that it looked like the right front

corner of the print didn't look as opaque as it did farther away from that

corner. I ran one of these bed level tests like I did when I was

getting set up to use the printer

and it came out that the right front corner didn't print. Time to

re-level the printer bed. Except I realized I didn't remember how to go

through the process of leveling the bed, so I gave up for the day.

Of the various channels I found on YouTube, the one I think I got the most from was CHEP, so I went to his channel, searched on bed leveling, and found a video that was dated a month ago. Obviously not the one I watched back last January, but I watched it and thought it was a big improvement over the way I did it. The main difference is that the previous video is based on sliding a piece of paper out from under the print head while this one is based on a feeler gauge. The 3D printed gun guys stress doing a better layer thickness calibration and I think they talked about using a feeler gauge.

To do this calibration, I needed to load some new firmware onto my printer, which required that I verify which processor board revision I have. I'd been meaning to do both of those things anyway.

With the new firmware and the bed leveled, it was time to print the revised design. Except that I hadn't put the Rev. 2 model's G-code on my memory card and printed Rev. 1. OK, time to really print Rev 2 and very quickly found a problem. The G-code was having it print the 1/8" thick part but left it the original 1/16" in the back. Then it went back to print the handle on top of that thinner area and it didn't even attach to it. A real mess. I ended up with two parts not really attached to each other.

Between the first layers looking thin, and the layers not bonding well when I printed the squares to check the bed level, I started to doubt this brand new yellow filament. So I removed it and put in the other new spool of PLA+ filament I have, this one white. I started printing with that and then broke for dinner. After eating I went to check it and found it had printed the bottom half of the 1/8" thick part and then got lost. The extruder went the width of the stick up in Y and some random offset to the right in X. Totally FUBAR. It left me puzzling over which piece of software screwed up or if it was the printer hardware. There's three possible sources of software errors: the new firmware in the printer, the slicer software that creates the G-code, or it could be that my CAD model had defects I can't see.

I decided to start everything over from scratch, except for leveling the bed. I redrew the model and sliced it with the other slicer software I have but switched away from, Cura. That required me to convert the model to metric in Rhino. That's not hard, just more to do and not having to do that is one reason I switched to the newer (to me) slicer software, Prusa. Then I started printing it again. This one worked fine and was done in an hour.

If you lost count, I had to print it three times to get one to come out right. The one that came out in two pieces is usable, I had to cut off the loose filament and glue that one together. I now have two of the sticks that I think will work and that's all I need. One will get 400 grit glued to it and the other will be more like 1000. Maybe. Probably?

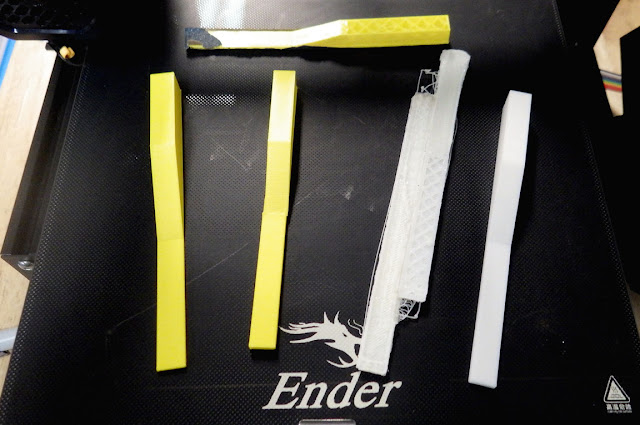

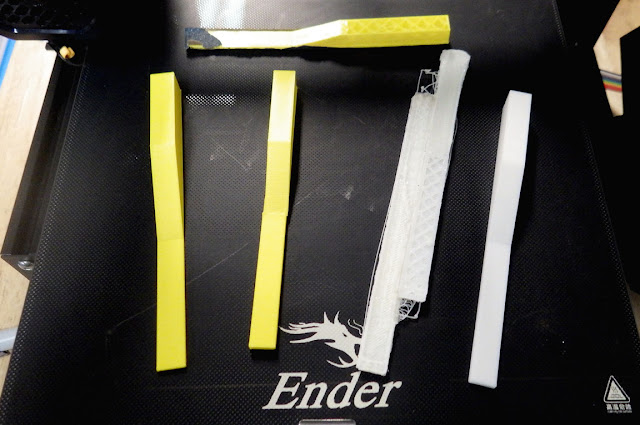

The Fat Popsicle Stick family. In the back is the Rev. 1 stick that popped off the bed before it was done, but was usable - except for being too wide. It has 220 sand paper glued to it and I actually ran that on the journal for a little while. The one on the left is the second Rev. 1 that I printed accidentally. Second from left is the first Rev. 2 that printed in two pieces. I shaved all the loops of filament off the bottom of the back's top piece and glued it to the bottom. The odd looking white mess is what came out of the printer losing its X and Y coordinates. The last one on the right is the finished Rev. 2 stick that printed properly.

Back in March of '17, I quoted an article from Machine Design magazine, "Are 3D Printers Overrated?" in a post for those of us who don't have one. The author's point was that you can buy a 2D printer (better known as an

inkjet or laser printer) set it up and get great results instantly. Go buy a 2D printer at your local office supply store and you'll be printing out grandma's recipes in less than an hour. 3D

printing is still a much, much less established technology.

I've had several prints that went without a hitch, but days like this week remind me of this guy's article. Yet another thing I've been thinking of doing is building an enclosure for my printer, which is his first recommendation.