There’s a handful of electronic components to choose from to help get rid of a surge from lightning. Diode rectifiers, zener diodes and special transient suppressor diodes are all widely used. One of the most widely used devices is an MOV (pronounced “em oh vee” not mauve) short for Metal Oxide Varistor. Varistor is a term for a variable resistor of any kind, and chances are you own some MOVs right now, built into something else you own, perhaps as a surge protected AC power strip. What makes MOVs variable is that as the voltage goes up, their resistance goes down. Because of that, they can dissipate that excess voltage as heat. That means they will eventually wear out and fail, so it’s best to construct the protector in a way that the MOVs can be removed and replaced (if it's not expected to be thrown out).

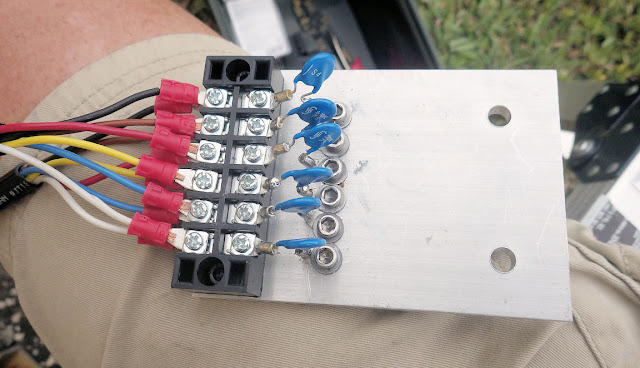

MOVs are usually two-leaded disks, made of a layer of Zinc Oxide with conducting terminals on either side. They are bidirectional, meaning they’ll react to pulses of either polarity, and the most common way to connect these is simply to put them in shunt to ground. There are six wires in my rotator control cable, all the voltages are DC and less than 25V, so I should be able to shunt the six wires to ground through six MOVs. MOVs can be paralleled to get more power handling capability.

Here’s a “do what I say not what I do” moment. MOVs should be chosen based on the operating conditions and not because you have some – which is what I did. This website, from industry giant Littlefuse, can help you choose an MOV, (that's a specific page in multi-page document) as can

this article from industry publication Electronic Design.

If you’re doing design for a living, you'll be paying attention to those selection criteria. For hams, the simplest Rule of Thumb (I like those) is to choose an MOV rated at 20% higher voltage than the normally expected voltage. In my case that would be above 30V. It so happens I have about hundred surplus 75V MOVs, which is three times my expected voltage and still very far below the anticipated lightning surge. The ones I have are rated at 2500 Amps on an 8/20 microsecond pulse (reaches peak in 8, declines to 50% at 20) or 12W for 2msec.

I simply need a way to break my cable and connect an MOV from all six wires to ground. That should be a robust ground connection.

Those two big holes on the right are how the metal plate local ground gets connected to the system ground: a stainless U-bolt with anti-seize compound.

Whenever you’re designing something like this, it seems to be an encouraging thing to discover that there’s a commercial product that does almost exactly the same thing. I found out midway through the design that amateur radio supplier DX Engineering has a product that’s conceptually identical to this, their Rotator Control Line Protectors, DXE-IS-RCT.

The major difference between theirs and mine is that they have two banks of four wire connections because some rotators have eight wires and theirs is a partially sealed box. Other differences are that I used stainless steel washers and cap screws for the MOV ground connections, although the terminal strip hardware isn’t stainless, and DX Engineering uses a more “professional” ground connector. Since I have an aluminum tower, I’m more concerned about dissimilar metals in contact than someone with a galvanized steel tower.

It's mounted to the tower with the stainless and aluminum interfaces smeared with an anti-seize compound that is also somewhat conductive. The ends of the cable I cut to expose those 12 wires, though completely insulated wires, and pretty much everything was coated with an outdoor, non-corrosive, RTV silicone rubber.

I will eventually have to replace this, and it's going to be a massive pain. It might be good to have some extras built and ready to swap out.

EDIT 3/14/20 2045 EDT: to lengthen the title. I'm going to search for this some day and the original title just isn't useful enough

I made up the same kind of box for the control and power leads out to my SGC autocoupler. I used a version of the AlpaDelta "arc plug" supressor instead of MOV's, and built it into a die-cast aluminum box that bolts to an 1/8" thick copper plate that bolts to my ground rod.

ReplyDeleteI'm putting one at the SGC, and one where the leads come into the house.

I think I would still do the Dr Toms knot in the input power cable of all units that plug into the power system. He swore it worked for lightning strikes, and lived in your neck of the woods. Said that if he forgot to do a new item in his house, that would be the only thing that would die in the next hit. Seems odd that a strike would blow the knot apart, but not pass any current onward, but he just stocked replacement cords for all his computers and peripherals, and everything else on the property. I figure it is really cheap insurance. Knot should be reasonably snug, IIRC. Something about it can't make the tight turn, and just goes straight. Too much mass in the bolt, perhaps?

ReplyDeleteThere’s a similar idea that’s got a good theoretical explanation: you’re making an inductor out of the cord. In an inductor, the voltage goes through easily but the current is impeded. A coiled power cord should be as effective as a knot and more predictable.

DeleteThe amount of power in the strike could blow the cord apart. The voltage getting through could still be a problem, though.

One of the first lightning protection tips I ever heard was to wind the feed line into a coil before it comes indoors, and put a spark gap on the house side of the coil. That tries to get both the current and the voltage.

I recall something about lightning protection on a sailboat, where a wide flat conductor works much better than normal wire. This is supposed to get on the good side of the skin effect for fast risetime/high frequency events.

ReplyDeleteI've heard that but never seen numbers for how much improvement there is. Flat ribbons are lower inductance than round wires, but that doesn't really answer all the questions. I'd want to know the DC resistance and the inductance, plus how that varies with how I mechanically arrange them. The online calculators have assumptions built in that probably won't be realistic.

DeleteI can go get pretty heavy stranded wire at the West Marine (boater's supplies) store easily. Copper strap is harder to come by.

Used a bunch of MOVs on a piece of avionics 30 years ago. It was an add-on box to an existing fighter. They did protect most of the electronics in the box when someone "accidently" swapped the 24V DC and 115 V/400 Hz inputs. But boy was the power supply board gubbered.

ReplyDeleteThe problem MOVs have is that they can fail open, which is the same as not having one any more. I'd really prefer some way of knowing it's bad.

DeleteSince has been nearly 30 years, the memories are dim but at least one of the MOVs was visibly open; the magic smoke had been released.

Deletenot much to do about a direct strike that won't still render expensive electronics into boat anchors, but there is good things said about transients protections. trans-i-trap(not a sponsor) devices use gallium arsenide transistor tech for a high speed shunt to ground. functionally, like a spark gap but no delay for the voltage to rise high enough to jump the spark gap so the damage is usually limited to the trap and outside cable. then there is the trans-i-trap at the line side of the power supply. has worked well for me since the day my C/Ka band dish equipment was fried by a very very close lightning strike-twenty meters away at a street light-back in the last century; which is what got me interested in the trans-i-trap in the first place.

ReplyDeleteMOVs on the line are helpful and do an ok job of it. Back in the day, I bought several replacement traps as spares as they are truly a one time use item but truly worth the cost.

So, I found something that works for me.

BITD, the Warning Stars had vac tubes which were very damage tolerant and easy(?) to renew; did get blasted by lightning on occasion. huge lightning arrestor spikes on the tip tanks and many, many static wicks. I recall one thrilling day when we had a ball lightning skip down the center aisle of the mission compartment of the aircraft leaving scorch marks on the flooring as it slowly dissipated. the HF antenna couplers simply fried and died when the antenna arrays took a hit. always wondered what was going on inside the fuel tanks when the hair on your head and arms started to stand up on end from the static build up.

Is Trans-i-trap still around? I've been doing searches with Duck Duck Go and everything is pointing to Alpha Delta. Alpha Delta refers to a gas-filled discharge tube ("ARC-PLUG"), not a GaAsFET.

DeleteThe protection on my coax inputs was by Alpha Delta 4B switches with the gas tubes. Those have National Stock Numbers and are used in a ton of .mil applications. I have to say they worked well; none of the radios had any effects of surge on their front ends.

I worked in this field over most of my 30 year career. First in EMP/HPM mitigation, later in EMC. The former was all about speed - gas tubes and zener type devices. Not much use for MOVs there, too much capacitance. Gas tubes were fun. You could use a multi-electrode device and a delay line to effect nearly instantaneous protection. In EMC and power supplies, the MOVs were useful and very important in protecting against line crosses - where it was assumed a 6 kV line would fall across a 230 V feeder, for example. The test were long and repetitious. Sometimes they failed. Nothing like coming in on a weekend to find a power supple EUT burning on the lab floor.

DeleteYeah, with rise times on the order of 5 nsec, EMP pulses are far too fast for an MOV. RF Filters are useful for the EMP pulse, if the system can live with the filters. I have gas tubes on my antenna switches, so some experience with GDTs, too.

DeleteThe old school way of dealing with lightning was to disconnect antennas outside if lightning was around. Since every day from about mid-May through mid-October has a chance of lightning and a lot of the rest of the year does as well, leaving cable connectors outside in the rain might be effective but not terribly practical. I thought we had a direct lightning strike but only later realized it had hit my palm tree. All the damage was from induced voltages/currents. Not everything damaged was plugged into the AC line, and not everything plugged in was damaged, so it's hard to see that unplugging everything would be effective.